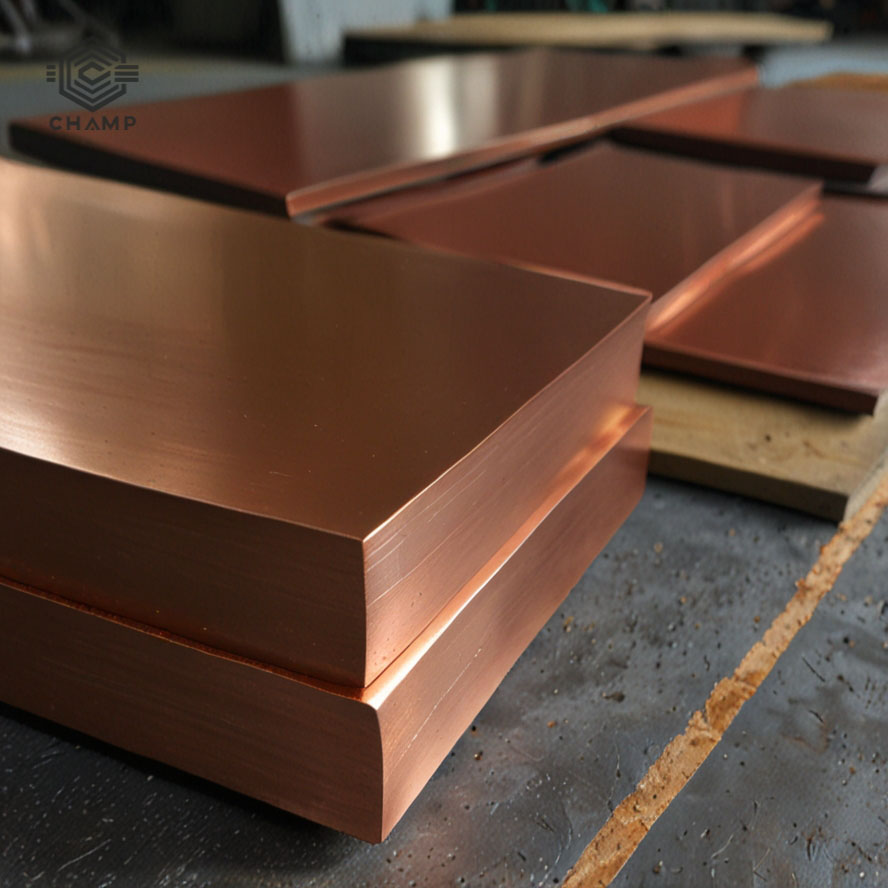

C17500 Beryllium Cobalt Copper Bars / Plates / Custom Machined Parts

Product Name:

C17500 Beryllium Cobalt Copper Bars / Plates / Custom Machined Parts

Material Overview:

C17500 is a high-performance beryllium-cobalt copper alloy that offers excellent electrical conductivity, high strength, and exceptional wear resistance. It is precipitation-hardened to enhance its mechanical properties and is widely used in industrial applications where both high conductivity and mechanical strength are required.

Standards Compliance:

ASTM B441 / B534 (U.S. Standard), RWMA Class 3

GB/T 5231 (China National Standard)

Chemical Composition (wt%):

Copper (Cu): Balance

Beryllium (Be): ~2.4%

Cobalt (Co): ~0.6%

Physical Properties:

Density: 8.6 g/cm³

Melting Point: Approx. 1029°C

Electrical Conductivity: 45–60 %IACS (depending on heat treatment condition)

Mechanical Properties (Aged Condition):

Tensile Strength: ≥ 793 MPa

Yield Strength: ≥ 758 MPa

Hardness: ≥ 230 HB

Elongation: ≥ 10%

Heat Treatment Parameters:

Solution Annealing Temperature: 900–980°C

Aging Temperature: 315–400°C

Available Specifications:

Round Bars: Diameter 3mm–200mm

Plates: Thickness 0.12mm–200mm

Custom Parts: CNC machining, welding, surface finishing available per drawing

Typical Applications:

Electrical contacts and relay components

Resistance welding electrodes and fixtures

Die casting mold inserts and nozzle seats

High-fatigue-resistance springs and precision fasteners

Aerospace pins and oilfield electrical conductors

Product Advantages:

✅ Combines high strength and electrical conductivity

✅ Stable performance after heat treatment, long service life

✅ Excellent wear and corrosion resistance for high-frequency operations

✅ Supports custom cutting, precision machining, low MOQ

Service & Guarantee:

✔ Material certificates and third-party inspection reports available

✔ Nationwide inventory, complete specifications in stock

✔ Export-ready with anti-corrosion and moisture-proof packaging