Inconel 740H

Inconel 740H

Inconel 740H is a nickel-based precipitation-hardened superalloy specifically designed to meet the demands of Advanced Ultra-Supercritical (A-USC) power plants operating in high-temperature and high-pressure environments between 700°C and 760°C.

Chemical Composition:

Element | Content (wt%) |

|---|---|

Nickel (Ni) | Balance |

Chromium (Cr) | 23.5–25.5 |

Cobalt (Co) | 15.0–22.0 |

Aluminum (Al) | 0.2–2.0 |

Titanium (Ti) | 0.5–2.5 |

Niobium (Nb) | 0.5–2.5 |

Iron (Fe) | ≤ 3.0 |

Carbon (C) | 0.005–0.08 |

Manganese (Mn) | ≤ 1.0 |

Molybdenum (Mo) | ≤ 2.0 |

Silicon (Si) | ≤ 1.0 |

Copper (Cu) | ≤ 0.5 |

Phosphorus (P) | ≤ 0.03 |

Sulfur (S) | ≤ 0.03 |

Boron (B) | 0.0006–0.006 |

The alloy achieves high strength through precipitation hardening, primarily via the γ’ (Ni₃(Al,Ti,Nb)) strengthening phase.

Physical Properties:

Density: 8.05 g/cm³

Melting Range: 1288–1362°C

Electrical Resistivity: 1.168 μΩ·m

Mechanical Properties (Room Temperature):

Yield Strength (0.2% offset): ~724 MPa

Ultimate Tensile Strength: ~1066 MPa

Elongation: ~23.7%

At elevated temperatures (700°C to 800°C), the alloy maintains high strength and good ductility.

Corrosion Resistance:

Inconel 740H exhibits excellent oxidation resistance and coal ash corrosion resistance at high temperatures, making it suitable for harsh environments such as coal-fired power plants.

Fabrication and Welding:

The alloy offers good workability and is suitable for both hot forming and cold working.

For welding, filler metals matching the base metal composition—such as Inconel 740H welding wire—are typically used. Common welding techniques include Gas Tungsten Arc Welding (GTAW), Pulsed Gas Metal Arc Welding (p-GMAW), and Hot Wire Gas Tungsten Arc Welding (HW-GTAW).

Applications:

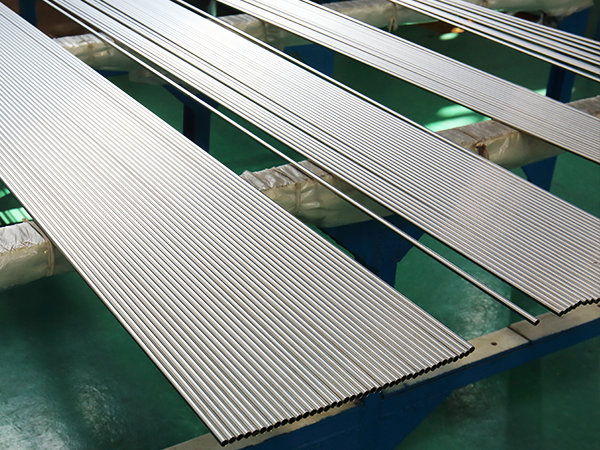

Due to its exceptional performance in high-temperature, high-pressure conditions, Inconel 740H is mainly used in critical components of A-USC power plants, such as boiler tubes, superheaters, and reheater piping.

Conclusion:

Inconel 740H is a high-performance nickel-based alloy that combines outstanding high-temperature strength, corrosion resistance, and processability, making it an ideal material choice for advanced ultra-supercritical power generation systems.