Inconel 718 (In718)

Inconel 718 (In718)

1. Overview

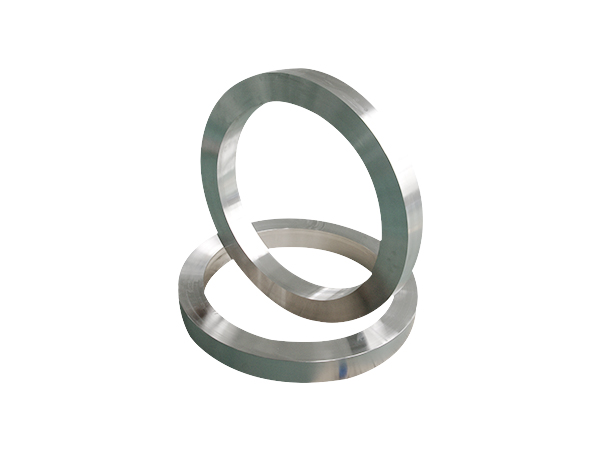

Inconel 718 is a nickel-based precipitation-hardening superalloy known for its high strength, excellent corrosion resistance, and oxidation resistance at high temperatures. It is widely used in aerospace, oil and gas, nuclear energy, and chemical industries. The alloy consists of elements such as nickel (Ni), chromium (Cr), iron (Fe), molybdenum (Mo), niobium (Nb), titanium (Ti), and aluminum (Al). Strengthening is achieved through precipitation of the γ″ phase (Ni₃Nb), ensuring outstanding mechanical performance under high-temperature environments.

2. Chemical Composition (Weight Percent)

Element | Content (wt%) |

Nickel (Ni) | 50.0–55.0 |

Chromium (Cr) | 17.0–21.0 |

Iron (Fe) | Balance |

Niobium (Nb) + Tantalum (Ta) | 4.75–5.50 |

Molybdenum (Mo) | 2.80–3.30 |

Titanium (Ti) | 0.65–1.15 |

Aluminum (Al) | 0.20–0.80 |

Manganese (Mn) | ≤0.35 |

Silicon (Si) | ≤0.35 |

Carbon (C) | ≤0.08 |

Sulfur (S) | ≤0.015 |

Phosphorus (P) | ≤0.015 |

Copper (Cu) | ≤0.30 |

Boron (B) | ≤0.006 |

3. Key Properties

Property Category | Value |

Density | 8.19 g/cm³ |

Melting Point | 1260–1336°C |

Tensile Strength (Rm) | ≥1275 MPa |

Yield Strength (Rp0.2) | ≥1035 MPa |

Elongation (A) | ≥12% |

Hardness (HRC) | 30–45 HRC (depending on heat treatment) |

Thermal Expansion (20–1000°C) | 13.0×10⁻⁶ /°C |

Thermal Conductivity (100°C) | 11.4 W/m·K |

Electrical Resistivity | 1.29 μΩ·m |

4. Key Characteristics

Excellent High-Temperature Strength: Maintains high strength and creep resistance between 650–980°C, ideal for prolonged high-temperature applications.

Superior Corrosion Resistance:

Highly resistant to oxidation, acidic environments (e.g., H₂SO₄, HNO₃, HCl), and seawater.

Excellent oxidation resistance in high-temperature atmospheres.

Good Weldability:

Compatible with TIG, MIG, electron beam welding, laser welding, etc.

Resistant to cracking post-welding; maintains good heat-affected zone performance.

Good Formability and Workability:

Can be cold or hot worked; due to high hardness, carbide or ceramic tools are recommended.

Stable Microstructure:

Solution + aging treatment promotes fine and uniform γ″ precipitation for improved mechanical properties.

5. Heat Treatment Process

Treatment Type | Temperature (°C) | Holding Time | Cooling Method |

Solution Treatment | 980–1065 | 1–2 hours | Water Quench |

First Aging | 720 | 8 hours | Air Cooling |

Second Aging | 620 | 8 hours | Air Cooling |

The purpose of heat treatment is to precipitate the strengthening γ″ phase (Ni₃Nb), improving strength and creep resistance.

6. Typical Applications

Aerospace:

Engine components (combustion chambers, turbine blades, turbine disks)

Rocket engine parts

Aircraft structural fasteners

Energy Sector:

Nuclear reactor components

Oil and gas drilling equipment

Corrosion-resistant offshore platform parts

Automotive:

Exhaust systems in racing engines

Chemical Industry:

Heat exchangers in acidic environments

High-temperature corrosion-resistant vessels

7. Inconel 718 vs. Other Superalloys

Alloy | Max Operating Temp (°C) | Creep Resistance | Oxidation Resistance | Weldability | Key Applications |

Inconel 718 | 980 | ★★★★☆ | ★★★★☆ | ★★★★★ | Jet engines, oil & gas |

Inconel 625 | 982 | ★★★☆☆ | ★★★★★ | ★★★★☆ | Chemical equipment, marine |

Waspaloy | 980 | ★★★★★ | ★★★★☆ | ★★☆☆☆ | Aircraft engines |

Rene 41 | 1100 | ★★★★★ | ★★★★★ | ★★☆☆☆ | Aerospace hot section parts |

Hastelloy X | 1200 | ★★★★☆ | ★★★★★ | ★★★★☆ | Gas turbines, petrochemical |

8. Machining and Use Precautions

Difficult to Machine: Due to high hardness and work-hardening tendency, use carbide or ceramic tools with low cutting speeds and high feed rates.

Avoid Prolonged High-Temperature Exposure: Prevents γ″ coarsening, which may reduce toughness and shorten service life.

Clean Surface Before Welding: Avoid contamination to ensure joint quality.

Prevent Hydrogen Embrittlement: In acidic environments, hydrogen levels must be controlled to prevent embrittlement.