β Titanium Alloy

QR code

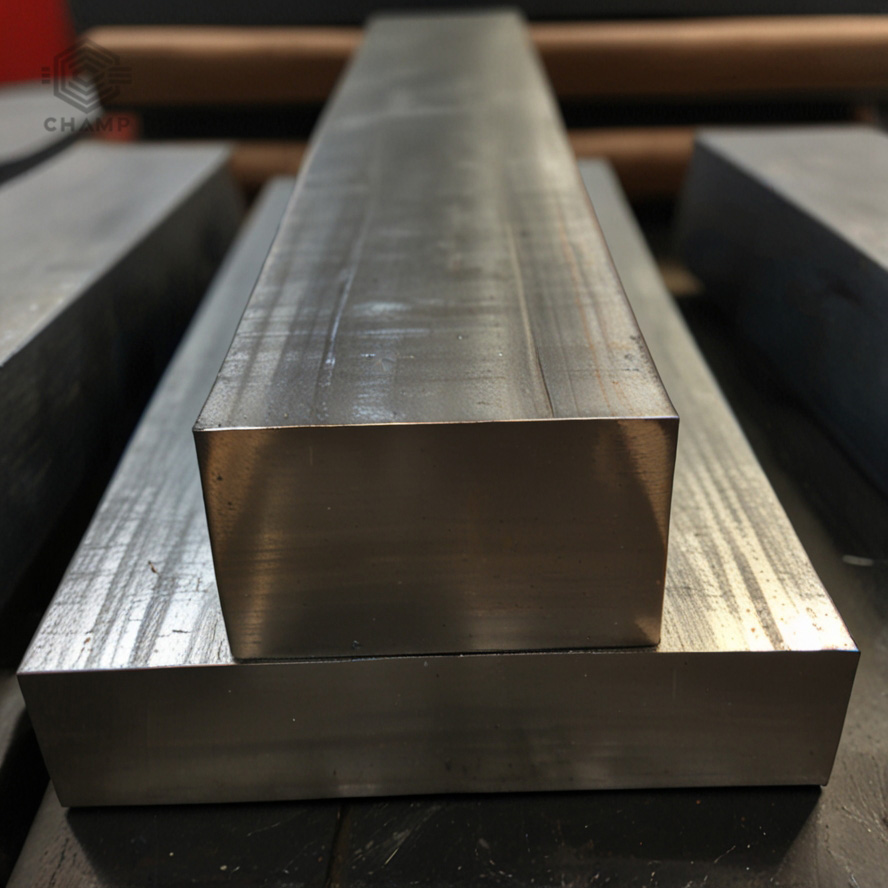

Detail

β Titanium Alloy

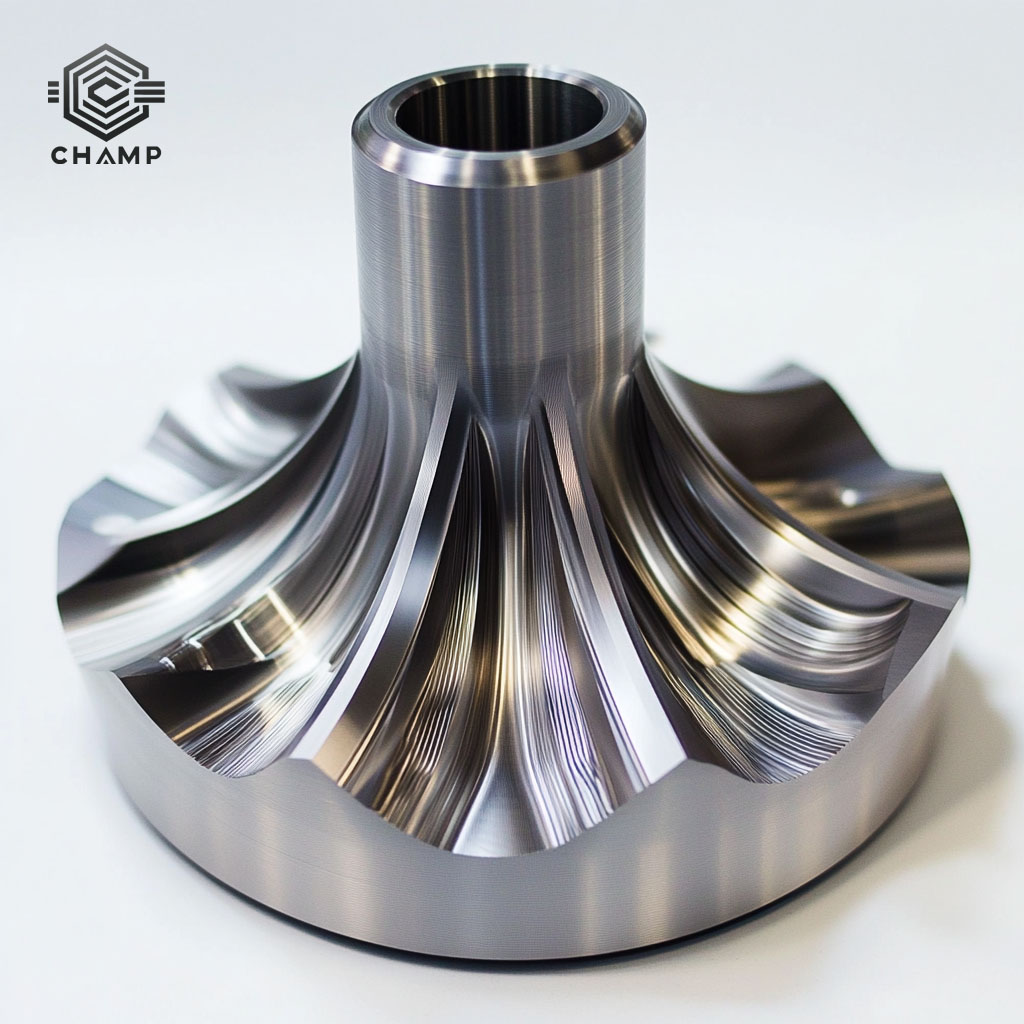

Overview

β titanium alloy is mainly composed of β stabilizing elements (such as Mo, V, Nb, Cr, Fe, etc.), with high β phase stability, and can maintain a single β phase structure under certain conditions. It has high strength without heat treatment, and the alloy is further strengthened after quenching and aging, and the room temperature strength can reach 1372~1666MPa; but the thermal stability is poor, and it is not suitable for use at high temperatures.

• α phase : The α phase of titanium is a hexagonal close-packed lattice (HCP structure), which is characterized by high strength, hardness, good high temperature performance and corrosion resistance. α titanium alloy is usually based on the α phase of pure titanium or titanium alloy, and its lattice structure enables it to exhibit excellent performance in high temperature and harsh environment.

• β phase : The β phase of titanium is a body-centered cubic lattice (BCC structure), which has better plasticity, but its strength at high temperatures is slightly lower than that of the α phase.

What is a β-stabilizing element?

Elements that preferentially dissolve in the β phase, lower the allotropic transformation temperature and expand the β phase region are β-stabilizing elements. According to the characteristics of their isomorphous effect, they are divided into two types: β isomorphous and B eutectoid.

(1) β-isomorphic stabilizing elements are infinitely dissolved in β-titanium, and as the solute elements increase, the allotropic transformation temperature gradually decreases, including molybdenum, vanadium, tantalum, and niobium.

(2) In addition to lowering the transformation temperature of the same type of heteromorphic transformation, the eutectoid stabilizing elements also have the effect of eutectoid transformation. The β phase is decomposed by eutectoid to form the a phase and intermetallic compounds. According to the difference in the eutectoid reaction rate, it can be further divided into two types: slow eutectoid elements (iron, chromium and manganese); active eutectoid elements (copper and silicon). The eutectoid transformation speed is extremely fast, and quenching cannot inhibit it, so the β phase cannot be stabilized to room temperature.

Compared with α and α+β titanium alloys, β titanium alloy has the following significant characteristics:

• High strength and high toughness : β titanium alloy can obtain high strength (over 1400 MPa) through heat treatment while maintaining good plasticity and toughness.

• Excellent hot processing performance : β titanium alloy has good high temperature plasticity and can be processed by hot forging, hot rolling, extrusion, drawing, etc., and is suitable for the preparation of large and complex components.

• Good welding performance : Compared with α and α+β alloys, β titanium alloy is less sensitive to welding and is suitable for laser welding, electron beam welding, tungsten inert gas welding, etc.

• High hardenability and heat treatment capability : can be solution- hardened and age-hardened to obtain excellent mechanical properties.

• Lower elastic modulus : lower than steel and α+β titanium alloy, suitable for use in biological implant materials, elastic components and other fields.

Common β titanium alloys and their compositions

β titanium alloys usually add β stabilizing elements to maintain the stability of the β phase. Common alloys include:

Alloy grade | Main components (mass %) | Features and Applications |

Ti-3Al-8V-6Cr-4Mo-4Zr (Beta C) | 3Al, 8V, 6Cr, 4Mo, 4Zr | High strength, high wear resistance, suitable for aviation landing gear, medical equipment |

Ti-10V-2Fe-3Al (Ti-1023) | 10V, 2Fe, 3Al | High strength, good hot workability, widely used in aviation structural parts |

Ti-5Al-5V-5Mo-3Cr (Ti-5553) | 5Al, 5V, 5Mo, 3Cr | Ultra-high strength, good hardenability, used in aircraft engines |

Ti-15Mo | 15Mo | Low elastic modulus, excellent biocompatibility, suitable for medical implants |

Ti-35Nb-7Zr-5Ta | 35Nb, 7Zr, 5Ta | Ultra-low elastic modulus, high biocompatibility, widely used in orthopedic implants |