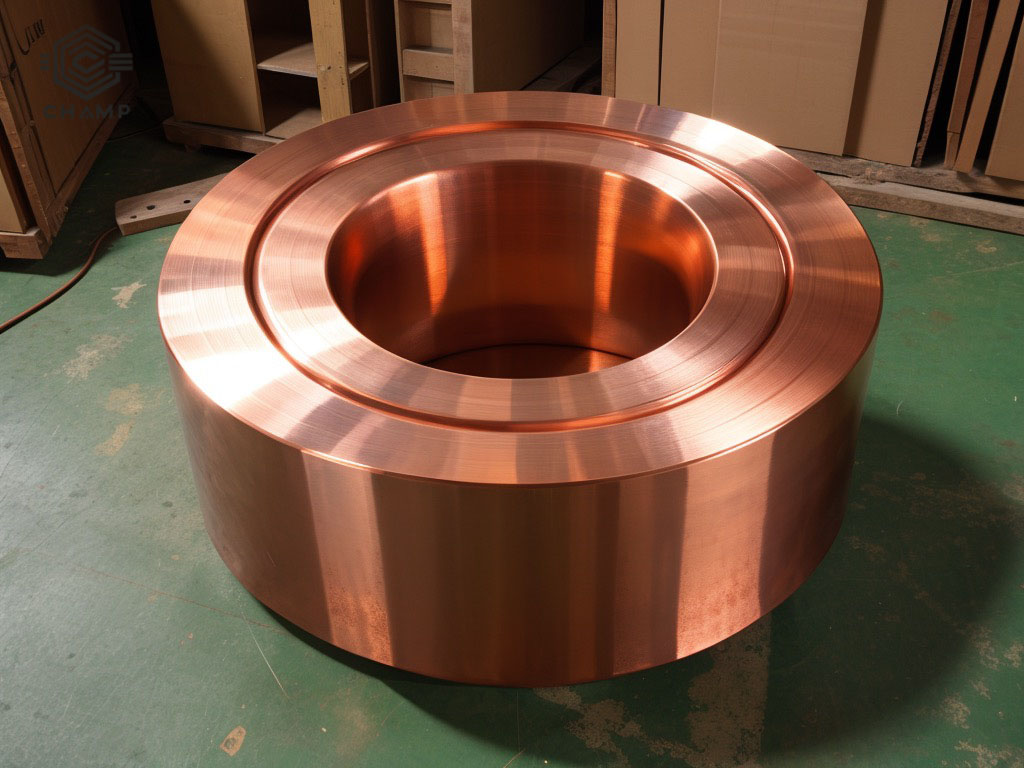

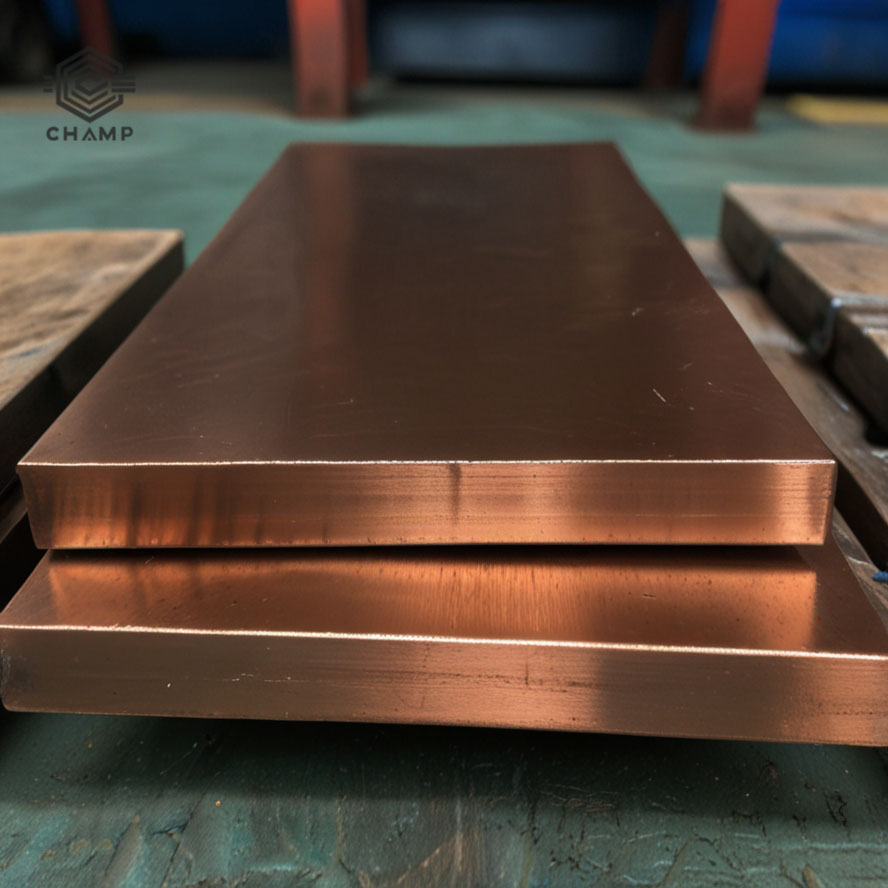

C18510 Chromium Zirconium Copper – Plates, Rods, Rings

Product Overview

C18510 Chromium Zirconium Copper is a high-performance copper alloy known for its excellent electrical and thermal conductivity, high strength, heat resistance, and wear resistance. It is an ideal material for a wide range of demanding industries, particularly in the fields of electrical and electronic equipment, resistance welding, power systems, aerospace, and heavy industry. Thanks to its outstanding comprehensive properties, C18510 significantly enhances service life and operational efficiency in these applications.

Physical Properties

Cr: 0.5–1.3%

Zr: 0.05–0.3%

Fe: 0.03%

Al: 0.038%

Si: 0.029%

Cu: Balance

Density: 8.94 g/cm³

Melting Point: 1,085–1,150°C

Electrical Conductivity: 80–85% IACS

Tensile Strength: 500–550 MPa

Yield Strength: 250–300 MPa

Elongation: 30–40%

Hardness: 120–160 HB

Thermal Conductivity: 380 W/m·K

Key Features

High Electrical Conductivity: Ensures efficient current transmission.

Excellent Thermal Conductivity: Enables rapid heat dissipation and enhances operational stability.

High Strength: Offers good tensile strength and wear resistance, suitable for high-load, long-term use.

Heat Resistance: Maintains performance under high temperatures and extreme thermal cycling.

Corrosion Resistance: Strong resistance to oxidation and corrosion, extending component lifespan.

Application Fields

Thanks to its exceptional combination of electrical/thermal conductivity, strength, and durability, C18510 Chromium Zirconium Copper is widely used in industries requiring high performance under extreme conditions, including:

Power & Electronics: Used in components such as transformers, power switches, contactors, transmission lines, and connectors, offering excellent conductivity and wear resistance.

Resistance Welding Electrodes & Continuous Casting Molds: Performs exceptionally in high-temperature, high-current environments, improving equipment longevity and reliability.