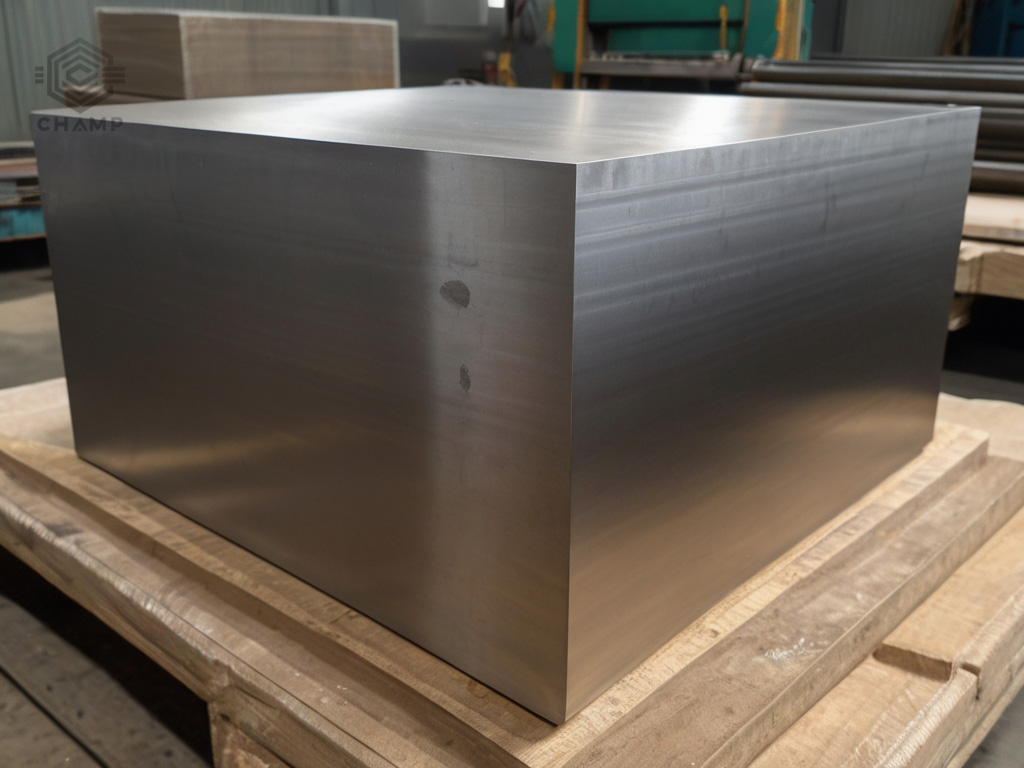

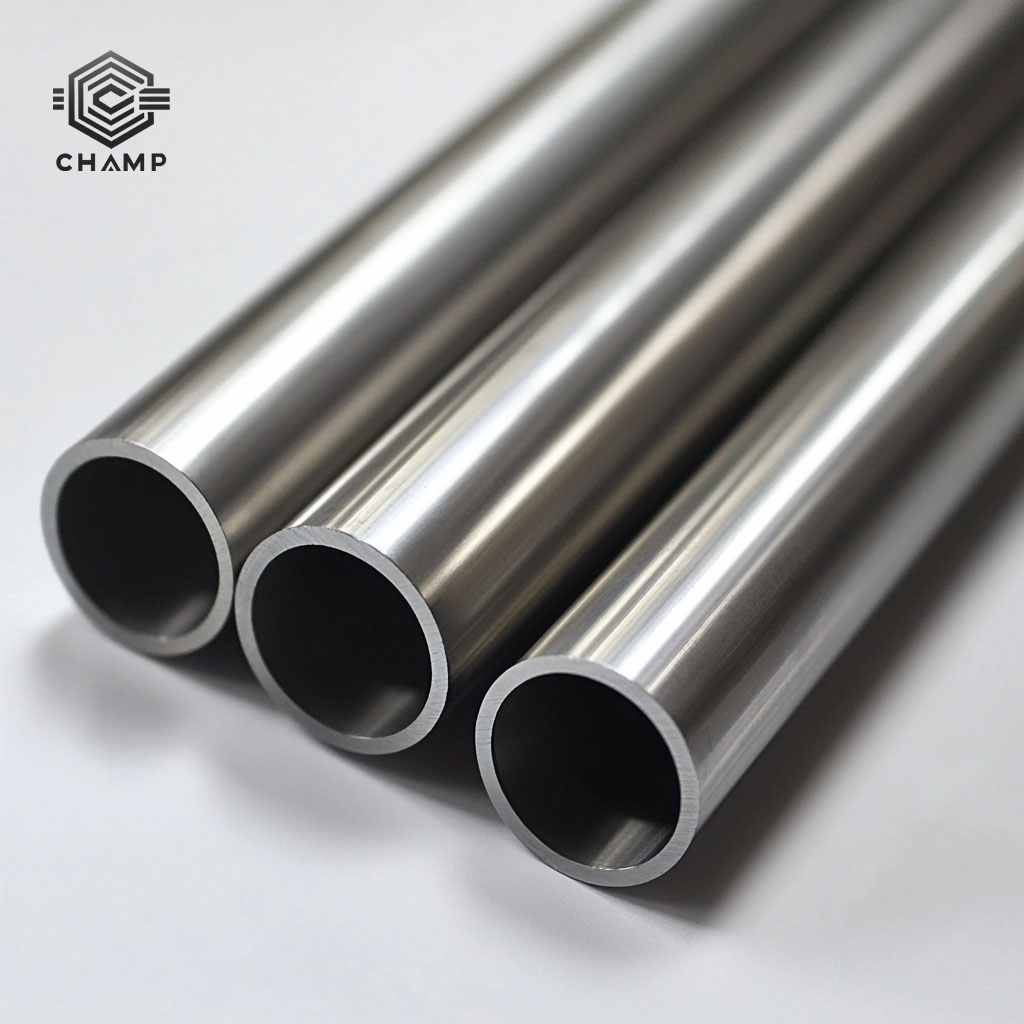

Ti6Al4V ELI (Grade 23) Titanium Alloy

QR code

Detail

Introduction to Ti-6Al-4V ELI

Ti-6Al-4V ELI (Extra Low Interstitial, ultra-low interstitial elements) is an improved version of Ti-6Al-4V (Grade 5) and is an α+β dual-phase titanium alloy. Its main feature is that, compared to regular Ti-6Al-4V, the ELI grade has lower impurity contents of oxygen, carbon, nitrogen, iron, etc., thereby improving the material’s toughness, fatigue resistance, and crack resistance. Due to its excellent biocompatibility, mechanical properties, and corrosion resistance, Ti-6Al-4V ELI is widely used in medical, aerospace, and high-end industrial manufacturing fields.

Its ultra-low interstitial element content gives it advantages over regular Ti-6Al-4V, making it especially suitable for applications requiring high fracture toughness and fatigue resistance.

Chemical Composition of Ti-6Al-4V ELI

The chemical composition of Ti-6Al-4V ELI meets standards such as ASTM F136, ASTM B348, and AMS 4907, as shown below (unit: %):

• Ti: balance

• Al: 5.5~6.5

• V: 3.5~4.5

• O ≤ 0.13

• C ≤ 0.08

• N ≤ 0.03

• H ≤ 0.0125

• Fe ≤ 0.25

Compared to regular Ti-6Al-4V (Grade 5), the ELI grade has a lower upper limit for oxygen content (0.13% vs. 0.20%), and stricter controls for interstitial elements like nitrogen and hydrogen.

Physical Properties of Ti-6Al-4V ELI

• Density: 4.44 g/cm³

• Melting point: 1604-1660°C

• Elastic modulus: 110 GPa

• Thermal conductivity: 6.6 W/m·K

• Specific heat capacity: 560 J/kg·K

• Electrical resistivity: 1.63×10⁻⁶ Ω·m

The combination of low density and high strength makes Ti-6Al-4V ELI an ideal choice for aerospace and medical implants.

Mechanical Properties of Ti-6Al-4V ELI

The mechanical properties of Ti-6Al-4V ELI are superior to regular Ti-6Al-4V (Grade 5), especially in low-temperature toughness and fatigue resistance.

Property | Annealed State | Heat-treated State |

Tensile Strength (MPa) | 860 - 970 | 1000 - 1100 |

Yield Strength (MPa) | 795 - 860 | 900 - 1000 |

Elongation (%) | 10 - 15 | 8 - 12 |

Fracture Toughness (MPa·m¹/²) | 50 - 100 | 40 - 80 |

Fatigue Strength (MPa) | 500 - 600 | 550 - 650 |

Ti-6Al-4V ELI retains good toughness even at low temperatures, making it suitable for applications in extreme environments such as deep-sea and aerospace.

Key Features of Ti-6Al-4V ELI

1. High Strength, Low Density

• Its strength is higher than most steel alloys, but its density is only about 57% of that of steel, making it a preferred material for lightweight, high-strength applications.

2. Excellent Corrosion Resistance

• It shows outstanding corrosion resistance in media such as seawater, acidic environments, and physiological fluids, making it particularly suitable for medical implants and marine engineering.

3. Outstanding Biocompatibility

• Due to its low toxicity, resistance to physiological corrosion, and good tissue compatibility, Ti-6Al-4V ELI is widely used in orthopedic and dental implants, such as artificial joints, bone plates, and dental implants.

4. Exceptional Toughness and Fatigue Resistance

• Due to its lower interstitial element content (O, N, C, H, etc.), Ti-6Al-4V ELI offers better fracture toughness and fatigue resistance than regular Grade 5 in low-temperature and high-cycle loading environments.

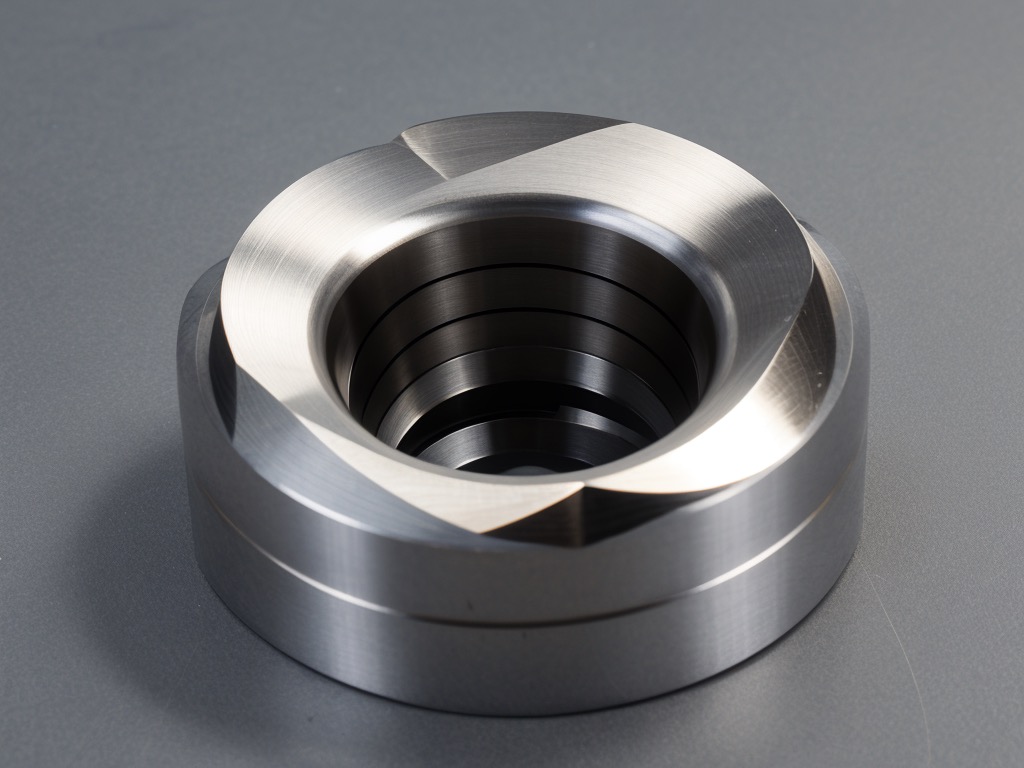

5. Good Workability

• It is suitable for various processing methods such as forging, machining, and 3D printing (SLM/EBM), capable of meeting different process requirements.

Applications of Ti-6Al-4V ELI

1. Medical Implants

• Orthopedics: Artificial joints (hip joints, knee joints), bone fixators, spinal implants

• Dentistry: Dental implants, dental bridges, orthodontic brackets

• Cardiovascular: Heart valve stents, implantable medical devices

• Surgical Instruments: Surgical knives, bone saws, forceps, etc.

2. Aerospace

• Airframe structural parts, engine components (e.g., rotors, fan blades)

• Spacecraft connectors, load-bearing structures

• Deep space exploration devices, satellite components

3. High-end Industry

• Marine Engineering: Deep-sea submersible hulls, underwater pipeline connectors

• Sports Equipment: High-end bicycle frames, golf clubs

• Automotive Manufacturing: Racing parts, such as suspension components, brake discs, etc.

Forming and Processing Notes

1. Machining

• Ti-6Al-4V ELI tends to work-harden, so sharp tools (such as tungsten carbide tools) should be used during cutting.

• It is recommended to use low-speed, high-feed rates and coolants to reduce tool wear.

2. Welding

• TIG welding, laser welding, and electron beam welding are feasible but should be performed in a vacuum or inert gas environment to prevent oxidation.

3. Heat Treatment

• Annealing: Heat at 700-850°C for 1-2 hours to improve toughness and machinability.

• Solution + Aging: Solutionize at 940-970°C and quench, then age at 500-600°C to improve strength.

4. 3D Printing

• Ti-6Al-4V ELI is suitable for Selective Laser Melting (SLM) and Electron Beam Melting (EBM) additive manufacturing, ideal for complex structures.

Ti-6Al-4V ELI vs. Ti-6Al-4V (Grade 5) Comparison

Property | Ti-6Al-4V (Grade 5) | Ti-6Al-4V ELI (Grade 23) |

Oxygen Content | 0.20% | 0.13% |

Yield Strength | 880-930 MPa | 795-860 MPa |

Fracture Toughness | 40-70 MPa·m¹/² | 50-100 MPa·m¹/² |

Fatigue Strength | 450-550 MPa | 500-600 MPa |

Main Uses | Industrial, Aerospace | Medical, Aerospace |