Titanium Grade 7 (Ti-0.2Pd)

QR code

Detail

Overview

Titanium Grade 7 (Ti-0.2Pd), with UNS designation R52400, is a high-performance corrosion-resistant titanium alloy. It is an α-type titanium alloy made by adding a small amount of the precious metal palladium (Pd) to commercially pure titanium. The addition of palladium significantly enhances the alloy’s corrosion resistance in reducing environments and improves its resistance in oxidizing environments. Among titanium alloys, Titanium Grade 7 exhibits the best crevice corrosion resistance in high-temperature and high-concentration chloride-containing environments. It shares similar applications with commercially pure titanium grades. However, due to the higher cost resulting from palladium content, Titanium Grade 7 is selected only when commercially pure titanium fails to meet performance requirements.

Titanium Grade 7 is primarily used in environments containing dilute hydrochloric acid, dilute sulfuric acid, and dilute phosphoric acid. It is also widely applied in titanium equipment to prevent crevice corrosion, such as in shell-and-tube heat exchangers and spinnerets in the textile industry. In acetaldehyde production plants, Titanium Grade 7 is extensively used for manufacturing titanium equipment, including flange liner rings and diamond gaskets. It is also employed in other installations for fabricating flanges and joints where crevices are present. Additionally, this alloy is utilized as a structural material in the production of C₂H₂Cl₂ (dichloroacetylene).

Titanium Grade 7 (Ti-0.2Pd) is an improved version of commercially pure titanium (Gr2). Due to its superior corrosion resistance in acidic and chloride environments, it is widely used in the chemical, marine, and energy industries. Although its mechanical properties are similar to those of Gr2, its enhanced corrosion resistance makes it advantageous in harsh environments.

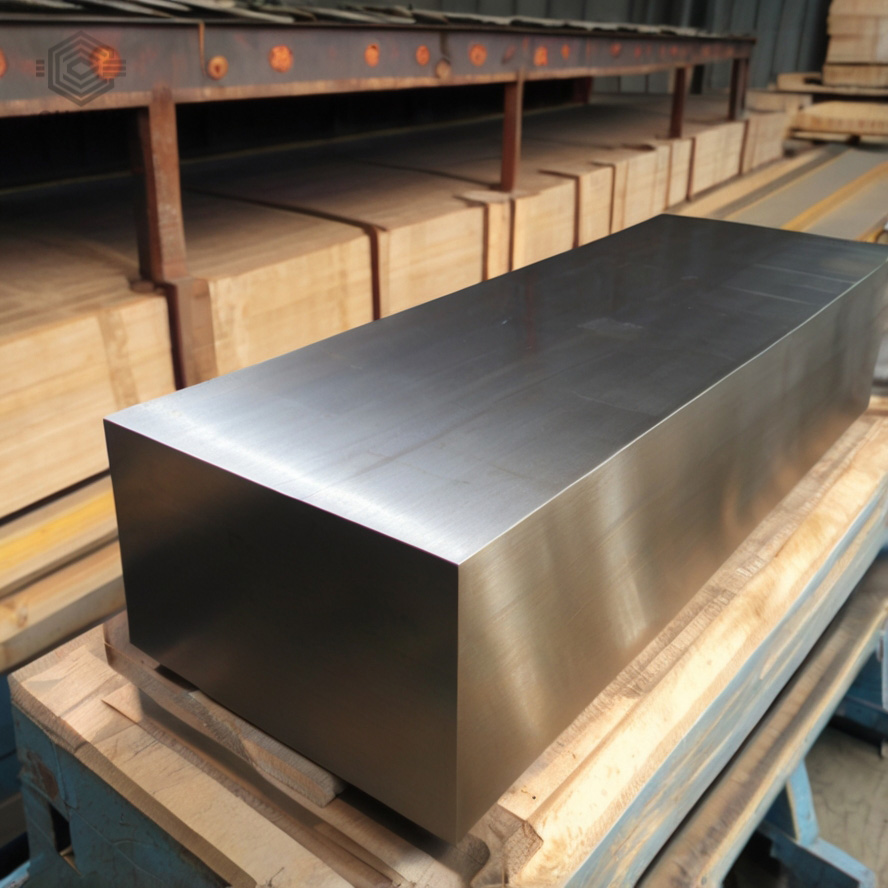

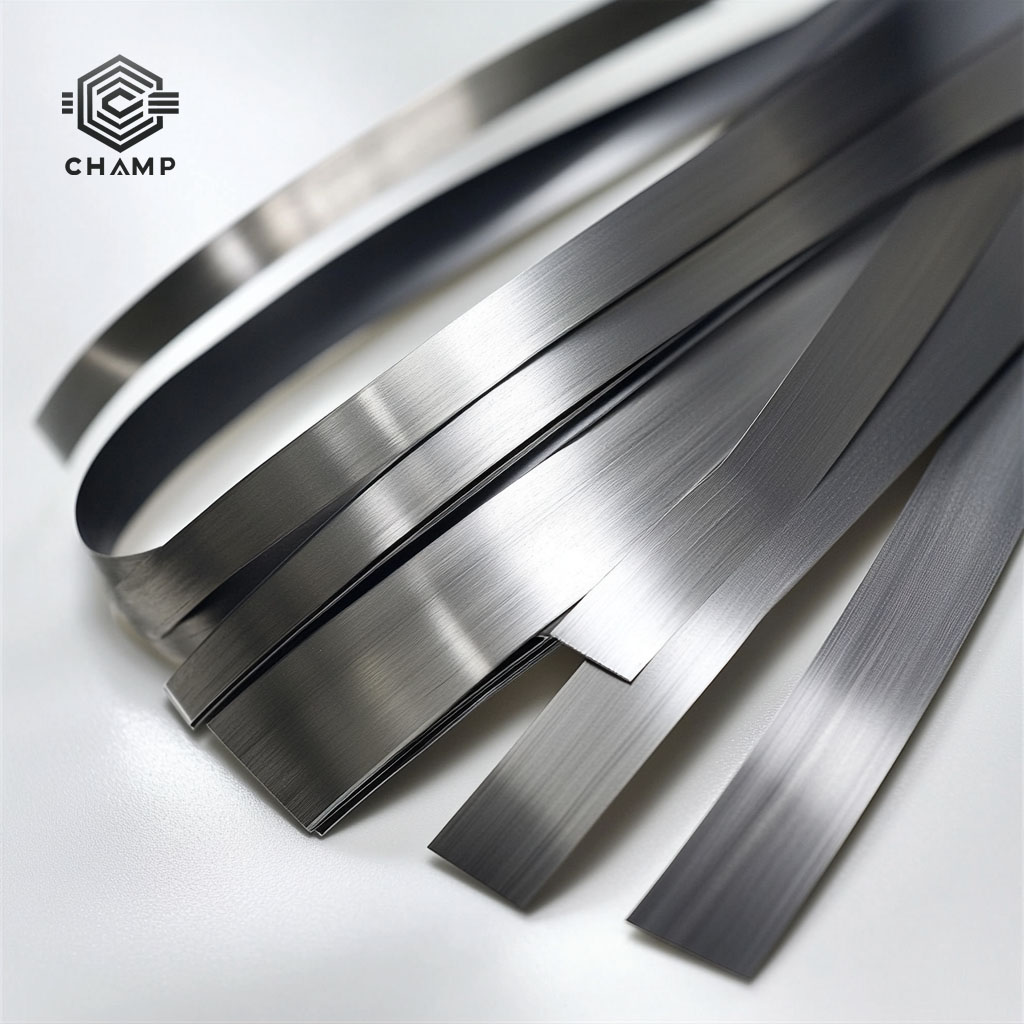

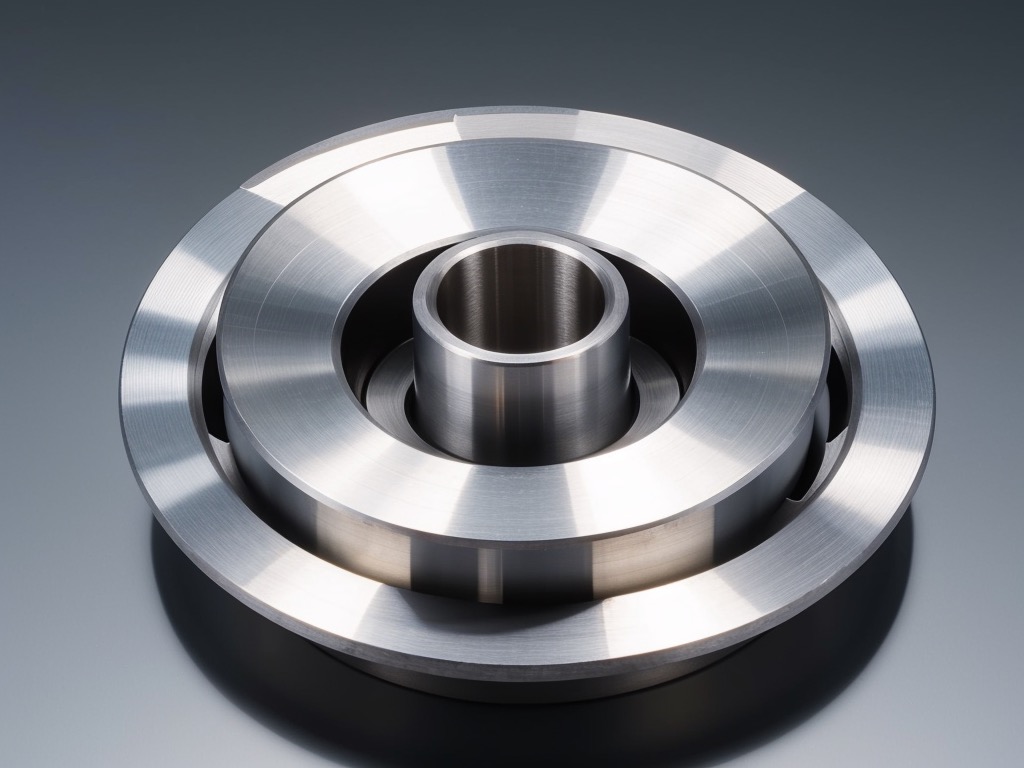

Product Forms

• Plate, bar, tube, strip, wire, casting, forging, machined parts

Alloy Properties

• Density: 4.52 g/cm³

• Elastic Modulus at Room Temperature: 103–107 GPa

• Poisson’s Ratio: 0.34–0.4

• Phase Transition Temperature: 913℃ ±15℃

• Hardness (HRB): 90–100

Chemical Composition (Mass Percentage, %)

• Titanium (Ti): Balance

• Palladium (Pd): 0.12–0.25

• Nitrogen (N): ≤0.03%

• Iron (Fe): ≤0.3%

• Oxygen (O): ≤0.25%

• Carbon (C): ≤0.08%

• Hydrogen (H): ≤0.015%

Key Features of Titanium Grade 7

1. Exceptional Corrosion Resistance

• Due to the presence of palladium, this alloy exhibits outstanding corrosion resistance in strong acids, chloride environments, and reducing conditions (e.g., seawater, acidic solutions, humid chlorine gas).

• It is highly suitable for extreme corrosive environments, such as the chemical industry, marine engineering, and chlor-alkali industry.

2. Good Mechanical Properties

• Its mechanical properties are similar to those of Titanium Grade 2 (Gr2) but perform better in high-temperature and highly corrosive environments.

• It has excellent weldability, with minimal degradation of properties in heat-affected zones (HAZ).

3. Excellent Workability

• It possesses similar forming and welding characteristics to Gr2 and can undergo heat treatment, welding, machining, and cold working.

4. Improved Resistance to Hydrogen Embrittlement

• The addition of palladium reduces the material’s sensitivity to hydrogen absorption, thereby mitigating hydrogen embrittlement and extending its service life.

Primary Applications

1. Chemical Industry

• Corrosion-resistant pipelines, storage tanks, heat exchangers, valves, pump casings

• Suitable for use in hydrochloric acid, sulfuric acid, phosphoric acid environments

• Chlor-alkali industry, electrolysis equipment

2. Marine Engineering

• Seawater desalination equipment

• Offshore platforms, ship pipelines, condenser heat exchanger tubes

3. Aerospace

• Fuel system components

• Structural support components

4. Medical Equipment

• Certain types of implants

• Surgical instruments

Comparison of Titanium Grade 7 with Other Titanium Alloys

Grade | Major Alloying Elements | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Applications |

Gr1 | Pure Titanium | 240 | 170 | General | Medical, Chemical |

Gr2 | Pure Titanium | 345 | 275 | Good | Chemical, Aerospace |

Gr7 | Ti-0.2Pd | 345 | 275 | Excellent | Chemical, Marine, Medical |

Gr5 | Ti-6Al-4V | 895 | 830 | General | Aerospace, Medical |

Gr9 | Ti-3Al-2.5V | 620 | 483 | Good | Aerospace, Bicycles |